- Home

-

Products

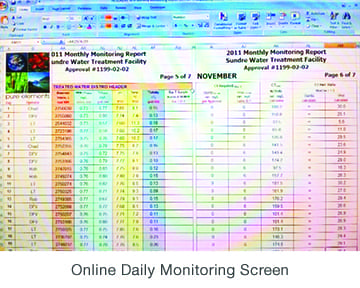

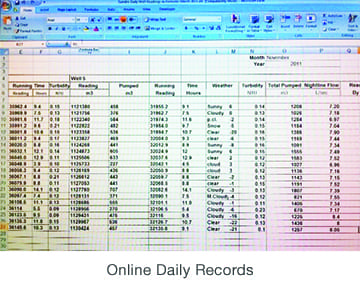

- Analyzers, Process Controllers & SCADA

- Anodes & Cathodes

- Aeration Systems

- Chemical Feed Equipment

- CH4, CO2, GHG Monitoring Systems

- Evaporators

- Facility Management Solutions

- Filtration Equipment

- Fire Suppression Solutions

- Incinerators

- Instruments & Reagents

- Lift Stations

- Mobile Water & Waste Solutions

- Packaged Water and Waste Systems

- Pumps

- Sodium Hypochlorite Generators

- Sorting & Recycling Stations

- Tanks

- Training

- Treatment Solutions

- Waste Management

- Work Camp Solutions

-

Services

- Audits & Assessments

- Budgeting

- Camp Services

- Climate Change

- Construction

- Documentation

- Emergency Services

- Engineering >

- Environmental

- Fire Suppression Management

- HSE / SAFETY

- Inactivation

- Modular / Mobile

- Quality Control

- Regional Systems

- Regulatory

- Rentals

- Remediation

- Start-Up

- Treatment Solutions

- Waste Management

- Waste-to-Energy

- Water / Waste Re-cycling

- Markets

- O & M

-

Treatment

- Aeration

- Ballasted Floc, Dissolved Air Flotation (DAF)

- Biosolids Management

- Clarification

- Coagulation, Flocculation

- CONTAMINANT REMOVAL >

- Disc Filters

- Disinfection

- ElectroChlorination

- Filtration

- GHG, CH4, CO2 Reduction

- Ion Exchange

- Membrane

- MVC, Thermal Evaporation

- Reverse Osmosis

- Thermal Treatment

- UltraViolet Disinfection

- Water & Waste Recycling

- Innovations

- About Us

- Contact Us

- Home

-

Products

- Analyzers, Process Controllers & SCADA

- Anodes & Cathodes

- Aeration Systems

- Chemical Feed Equipment

- CH4, CO2, GHG Monitoring Systems

- Evaporators

- Facility Management Solutions

- Filtration Equipment

- Fire Suppression Solutions

- Incinerators

- Instruments & Reagents

- Lift Stations

- Mobile Water & Waste Solutions

- Packaged Water and Waste Systems

- Pumps

- Sodium Hypochlorite Generators

- Sorting & Recycling Stations

- Tanks

- Training

- Treatment Solutions

- Waste Management

- Work Camp Solutions

-

Services

- Audits & Assessments

- Budgeting

- Camp Services

- Climate Change

- Construction

- Documentation

- Emergency Services

- Engineering >

- Environmental

- Fire Suppression Management

- HSE / SAFETY

- Inactivation

- Modular / Mobile

- Quality Control

- Regional Systems

- Regulatory

- Rentals

- Remediation

- Start-Up

- Treatment Solutions

- Waste Management

- Waste-to-Energy

- Water / Waste Re-cycling

- Markets

- O & M

-

Treatment

- Aeration

- Ballasted Floc, Dissolved Air Flotation (DAF)

- Biosolids Management

- Clarification

- Coagulation, Flocculation

- CONTAMINANT REMOVAL >

- Disc Filters

- Disinfection

- ElectroChlorination

- Filtration

- GHG, CH4, CO2 Reduction

- Ion Exchange

- Membrane

- MVC, Thermal Evaporation

- Reverse Osmosis

- Thermal Treatment

- UltraViolet Disinfection

- Water & Waste Recycling

- Innovations

- About Us

- Contact Us